loading

K6000

Reanin

8424899990

| polyurea for waterproof | polyurea spraying on ground for waterproof and anti-corrosion. | pu foaming for car interior insulation |

|  |  |

| pu foaming machine for container insulation | K6000 hydraulic polyurea polyurethane foam spray machine. |

|  |

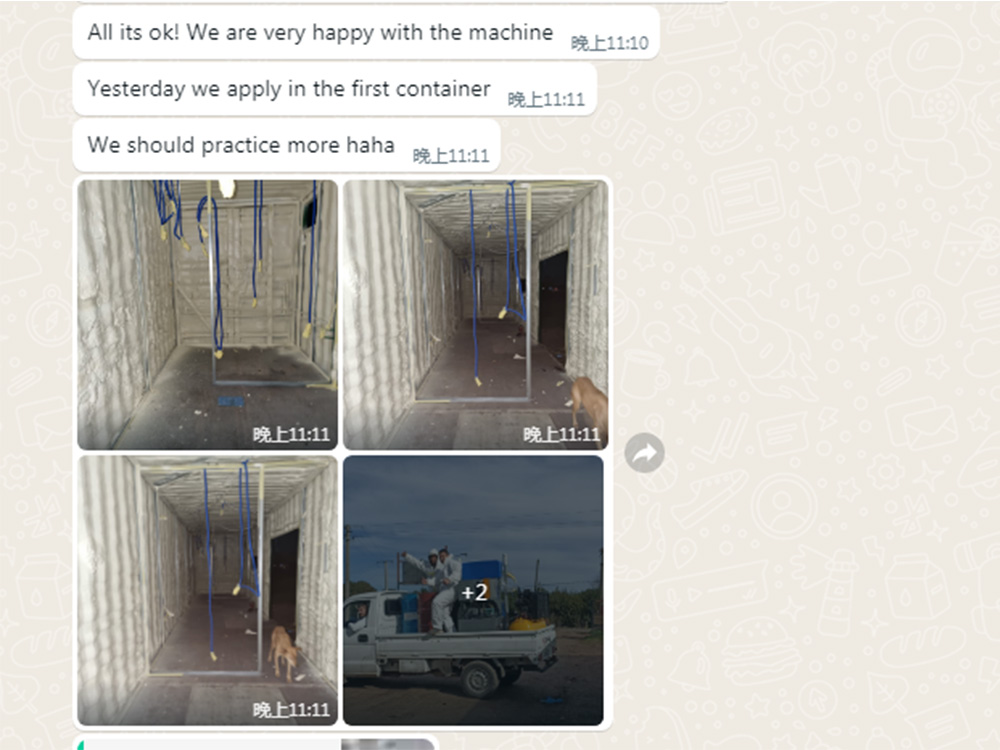

| Polyurethane foam spraying and injection for insulation in large industrial | Nice comment from our customer about K6000 machine |

|  |

Product Introduction

K6000 is a hydraulically driven polyurethane polyurea spray machine. It has the characteristics high working pressure, stable pressure and large spray output. It is especially suitable for large-scale spraying construction.

Reanin K6000 High pressure pu foam and polyurea coating Machine can be widely used in construction building roof and wall insulation, roof waterproofing, swimming pool waterproofing,pipe insulation, tank , cold storage thermal insulation, stadium ground and spectator seats waterproofing,highway subgrade waterproofing or repairing, railway subgrade waterproofing, automobile thermal insulation and sound insulation, ship anti-corrosion and waterproofing and so on.

Product Advantage

•This machine has pass the CE Certificate,

•Panel with operation tips is easy to set up,

•Equipped with hydraulic station, the working pressure is stable, and the effect of continuous spraying for a long time is good,

•The high-speed circulating lubricating fluid in the anti-curing lubrication cylinder can quickly take away the leakage of materials, and the ISO pump shaft is always immersed in the lubricating fluid to avoid crystallization,

•A/B/Hose independent temperature control, can set different temperatures separately, adapt to the temperature requirements of different materials,

•Variable frequency temperature control mode and special real-time temperature collection sensor ensure that the material temperature is controlled within a small fluctuation range,

•The heated hose is wrapped around the heating belt, the heating is fast and uniform, and covered with the insulation and protective cover, which is safe and durable,

•The transfer pumps, mainframe and spray gun are equipped with filtering devices, which can

effectively filter impurities and crystals in the materials and reduce the occurrence of the blocking gun,

•High-precision pressure gauges are available in MPa and PSI to meet the needs of different customers,

•Equipped with an action counter to accurately calculate the amount of raw materials,

The spray gun is made of alloy material, light weight, less wearing parts, easy to use and maintain.

Technical Parameters

| Model | Reanin-K6000 polyurethane and polyurea spray machine |

| Applicable materials | Polyurethane and Polyurea |

| The ratio of raw material | 1:1 |

| Viscosity range of raw materials | 200-1000CPS (under working temperature) |

| Max working pressure | 25MPa |

| Max fluid temperature | 80°C |

| Max output | 15kg/min |

| Max heated hose length (Optional) | 90m |

| Heater power | 4500W×2 |

| Heated hose max power | 3000W |

| Drive mode | Hydraulic |

| Clean mode | Self-cleaning by air |

| Voltage (Optional) | Three phase 220V 60Hz or Three phase 380V 50Hz |

| Whole power | 17kw |

| Pneumatic source | 0.5-0.8Mpa 1m³/min |

Product Uses

Here are some specific application scenarios of polyurea spray machine:

1. Two component polyurethane foam spray machine can be used in construction building roof and wall insulation ,and cold storage thermal insulation, and mobile home insulation, and container, car interior thermal insulation.

2. Two component pu foam machine can be used in pipe insulation with injection gun, it can also spray&injection on tank for insulation.

3. Two component rigid foam spraying machine can be also used in Industrial commercial purpose , such as chicken house insulation project, door panel injection foam projects, cold storage house panel insulation, Greenhouse insulation projects, and so on.

4. Hydraulic polyurea spraying machine can be used in roof waterproofing, swimming pool waterproofing,stadium ground and spectator seats waterproofing,highway subgrade waterproofing or repairing, railway subgrade waterproofing, automobile thermal insulation and sound insulation, ship anti-corrosion and waterproofing and so on.

Product Operate Guide

Working principle

This system uses compressed air from the air compressor and hydraulic pressure from the hydraulic station as the source of power.The air compressor provides compressed air as power for the feed pump and spray gun,the motor of the hydraulic system of the main engine drives the plunger pump. The plunger pump delivers hydraulic oil to the booster pump of the main engine to provide power for the booster pump.The transfer pump at work extracts and transports the A and B materials in the barrel to the mainframe respectively. The main working part of the mainframe is a double-acting hydraulic booster pump, and the reversing mechanism is an electromagnetic reversing device.

After the hydraulic oil of the host enters the hydraulic motor of the booster pump, when the motor piston moves to the left or right end, the left proximity switch or the right proximity switch is induced to control the instantaneous commutation of the solenoid valve, so that the piston of the hydraulic motor performs stable and continuous reciprocation motion.Since the piston of the hydraulic motor is rigidly connected to the piston in the booster pump, and the area of the piston of the hydraulic motor is larger than the area of the piston of the booster pump, the raw material entering the booster pump is pressurized.The pressurized raw material quickly reaches the preset temperature when passing through the heating unit, and is delivered to the spray gun through the high-pressure heating hose, and finally mixed in the spray gun, and sprayed to the surface of the object after instantaneous atomization.

Hydraulic System Maintenance

In the hydraulic system, the hydraulic oil purity and oil content are very import.

If the hydraulic oil include impurities will cause the whole system not work. So much ensure the system oil purity.

System oil shortage can easily lead to excessive temperature rise too fast, leaving the viscosity of hydraulic oil lower, resulting in system pressure is too low and affect the work of system. Usually the amount of hydraulic oil should be 2/3 level.

How to choose the hydraulic oil?

According the different regions of the ambient temperature difference to choose a different hydraulic oil to ensure the normal operation of the system.

Generally use more than 68# hydraulic oil.

For temperature below 5℃, should use 32# or 48# hydraulic oil.

FAQ

Q: Where is your company? Are you the manufacturer?

A:Yes, We are manufacturer, located in Jinan city, Shandong province.

Q: What's the warranty on this machine?

A: We provide one year warranty, and support lifelong consultant service.

Q: How can I get the spare parts for the machine?

A: We will send a set of additional spare parts along with the goods. International express is available when needed, which usually arrives in about 7 days.

Q: Is it in stock? When is the delivery date?

A: We will send the machine out within 7-10 days after receiving your payment, (Excluding customized products).

Q: I am new at this, How to use the machine?

A: Our machine is easy to opperate, we provide user manual and videos,We offer online guidance services.

| polyurea for waterproof | polyurea spraying on ground for waterproof and anti-corrosion. | pu foaming for car interior insulation |

|  |  |

| pu foaming machine for container insulation | K6000 hydraulic polyurea polyurethane foam spray machine. |

|  |

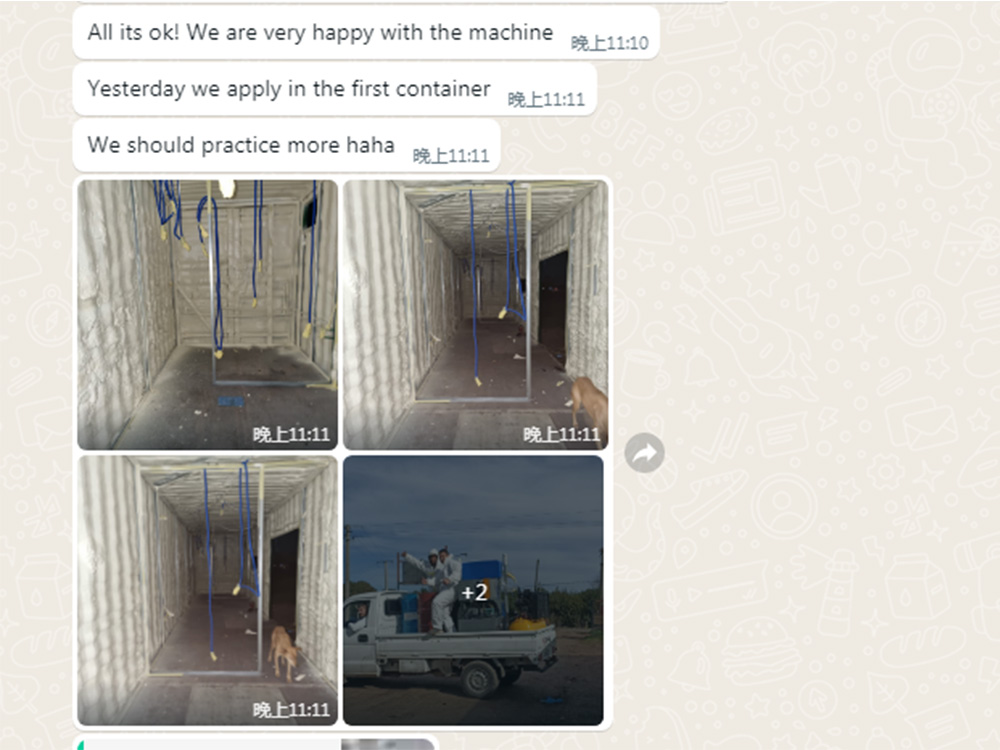

| Polyurethane foam spraying and injection for insulation in large industrial | Nice comment from our customer about K6000 machine |

|  |

Product Introduction

K6000 is a hydraulically driven polyurethane polyurea spray machine. It has the characteristics high working pressure, stable pressure and large spray output. It is especially suitable for large-scale spraying construction.

Reanin K6000 High pressure pu foam and polyurea coating Machine can be widely used in construction building roof and wall insulation, roof waterproofing, swimming pool waterproofing,pipe insulation, tank , cold storage thermal insulation, stadium ground and spectator seats waterproofing,highway subgrade waterproofing or repairing, railway subgrade waterproofing, automobile thermal insulation and sound insulation, ship anti-corrosion and waterproofing and so on.

Product Advantage

•This machine has pass the CE Certificate,

•Panel with operation tips is easy to set up,

•Equipped with hydraulic station, the working pressure is stable, and the effect of continuous spraying for a long time is good,

•The high-speed circulating lubricating fluid in the anti-curing lubrication cylinder can quickly take away the leakage of materials, and the ISO pump shaft is always immersed in the lubricating fluid to avoid crystallization,

•A/B/Hose independent temperature control, can set different temperatures separately, adapt to the temperature requirements of different materials,

•Variable frequency temperature control mode and special real-time temperature collection sensor ensure that the material temperature is controlled within a small fluctuation range,

•The heated hose is wrapped around the heating belt, the heating is fast and uniform, and covered with the insulation and protective cover, which is safe and durable,

•The transfer pumps, mainframe and spray gun are equipped with filtering devices, which can

effectively filter impurities and crystals in the materials and reduce the occurrence of the blocking gun,

•High-precision pressure gauges are available in MPa and PSI to meet the needs of different customers,

•Equipped with an action counter to accurately calculate the amount of raw materials,

The spray gun is made of alloy material, light weight, less wearing parts, easy to use and maintain.

Technical Parameters

| Model | Reanin-K6000 polyurethane and polyurea spray machine |

| Applicable materials | Polyurethane and Polyurea |

| The ratio of raw material | 1:1 |

| Viscosity range of raw materials | 200-1000CPS (under working temperature) |

| Max working pressure | 25MPa |

| Max fluid temperature | 80°C |

| Max output | 15kg/min |

| Max heated hose length (Optional) | 90m |

| Heater power | 4500W×2 |

| Heated hose max power | 3000W |

| Drive mode | Hydraulic |

| Clean mode | Self-cleaning by air |

| Voltage (Optional) | Three phase 220V 60Hz or Three phase 380V 50Hz |

| Whole power | 17kw |

| Pneumatic source | 0.5-0.8Mpa 1m³/min |

Product Uses

Here are some specific application scenarios of polyurea spray machine:

1. Two component polyurethane foam spray machine can be used in construction building roof and wall insulation ,and cold storage thermal insulation, and mobile home insulation, and container, car interior thermal insulation.

2. Two component pu foam machine can be used in pipe insulation with injection gun, it can also spray&injection on tank for insulation.

3. Two component rigid foam spraying machine can be also used in Industrial commercial purpose , such as chicken house insulation project, door panel injection foam projects, cold storage house panel insulation, Greenhouse insulation projects, and so on.

4. Hydraulic polyurea spraying machine can be used in roof waterproofing, swimming pool waterproofing,stadium ground and spectator seats waterproofing,highway subgrade waterproofing or repairing, railway subgrade waterproofing, automobile thermal insulation and sound insulation, ship anti-corrosion and waterproofing and so on.

Product Operate Guide

Working principle

This system uses compressed air from the air compressor and hydraulic pressure from the hydraulic station as the source of power.The air compressor provides compressed air as power for the feed pump and spray gun,the motor of the hydraulic system of the main engine drives the plunger pump. The plunger pump delivers hydraulic oil to the booster pump of the main engine to provide power for the booster pump.The transfer pump at work extracts and transports the A and B materials in the barrel to the mainframe respectively. The main working part of the mainframe is a double-acting hydraulic booster pump, and the reversing mechanism is an electromagnetic reversing device.

After the hydraulic oil of the host enters the hydraulic motor of the booster pump, when the motor piston moves to the left or right end, the left proximity switch or the right proximity switch is induced to control the instantaneous commutation of the solenoid valve, so that the piston of the hydraulic motor performs stable and continuous reciprocation motion.Since the piston of the hydraulic motor is rigidly connected to the piston in the booster pump, and the area of the piston of the hydraulic motor is larger than the area of the piston of the booster pump, the raw material entering the booster pump is pressurized.The pressurized raw material quickly reaches the preset temperature when passing through the heating unit, and is delivered to the spray gun through the high-pressure heating hose, and finally mixed in the spray gun, and sprayed to the surface of the object after instantaneous atomization.

Hydraulic System Maintenance

In the hydraulic system, the hydraulic oil purity and oil content are very import.

If the hydraulic oil include impurities will cause the whole system not work. So much ensure the system oil purity.

System oil shortage can easily lead to excessive temperature rise too fast, leaving the viscosity of hydraulic oil lower, resulting in system pressure is too low and affect the work of system. Usually the amount of hydraulic oil should be 2/3 level.

How to choose the hydraulic oil?

According the different regions of the ambient temperature difference to choose a different hydraulic oil to ensure the normal operation of the system.

Generally use more than 68# hydraulic oil.

For temperature below 5℃, should use 32# or 48# hydraulic oil.

FAQ

Q: Where is your company? Are you the manufacturer?

A:Yes, We are manufacturer, located in Jinan city, Shandong province.

Q: What's the warranty on this machine?

A: We provide one year warranty, and support lifelong consultant service.

Q: How can I get the spare parts for the machine?

A: We will send a set of additional spare parts along with the goods. International express is available when needed, which usually arrives in about 7 days.

Q: Is it in stock? When is the delivery date?

A: We will send the machine out within 7-10 days after receiving your payment, (Excluding customized products).

Q: I am new at this, How to use the machine?

A: Our machine is easy to opperate, we provide user manual and videos,We offer online guidance services.