loading

| Availability: | |

|---|---|

| Quantity: | |

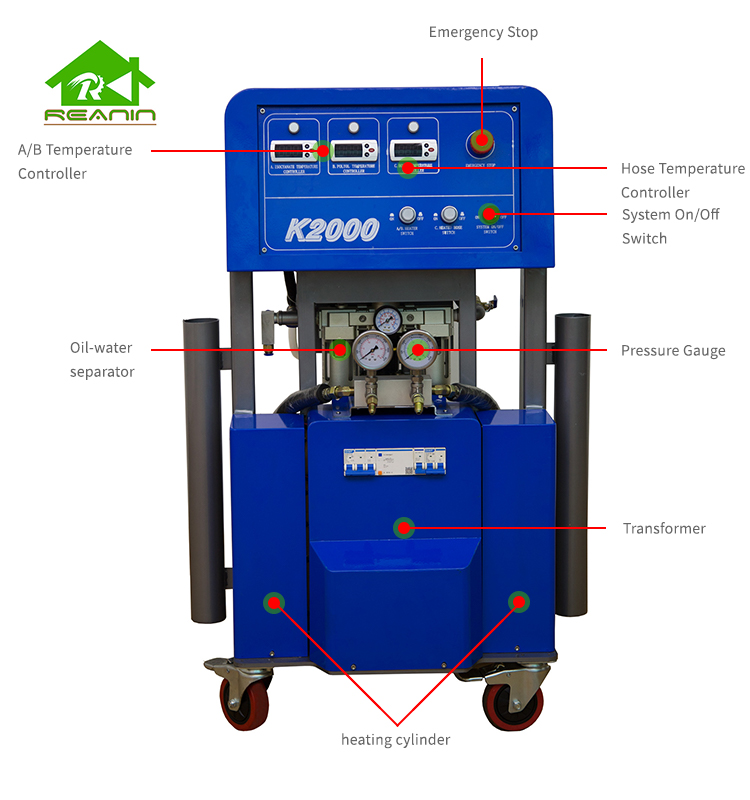

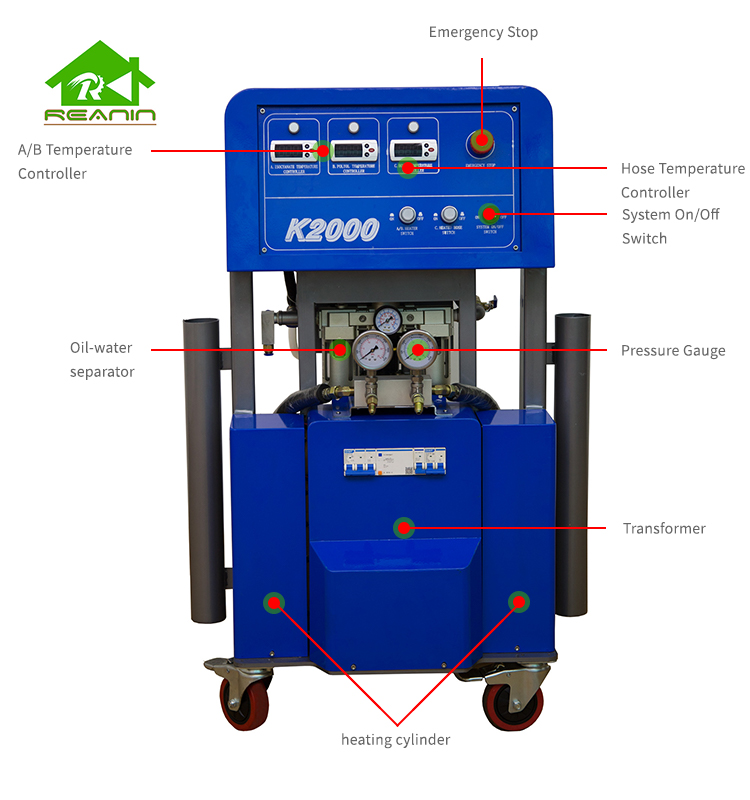

K2000

Reanin

8424899990

Product Introduction

Reanin K2000 portable polyurethane spray machine is a pneumatic two-component polyurethane spray injection machine. It is suitable for building interior and exterior wall and roof insulation, pipe insulation, economical, easy to operate and maintain, and is an indispensable sprayer in the polyurethane technical solution.

Product Advantage

1."Reanin-K2000 Portable Pu Foam Spray Insulation Machine": Customers can achieve a variety of spraying tasks with the versatility of the Reanin-K2000 portable polyurethane spray machine.

2."Competitive Factory Price": The Reanin-K2000 spray foam insulation machine is offered at a highly competitive factory price, making it an attractive and cost-effective solution for users.

3."Full Pneumatic Drive Model": The Reanin-K2000 features a full pneumatic drive model, ensuring superior performance and effectiveness in a variety of spraying tasks, including foam insulation jobs.

4."Self-Cleaning by Air": The machine offers a user-friendly self-cleaning system, where cleaning can be done easily and quickly, saving users time and effort.

5."Core Components of Motor": The product's key selling points also include the use of superior core components such as a motor, pump, and engine, which ensure the machine's reliability and durability over the 1-year warranty period.

Technical Parameters

| Model | Reanin-K2000 Polyurethane Spray Machine |

| Applicable materials | Polyurethane |

| The ratio of raw material | 1:1 |

| Viscosity range of raw materials | 200-1000CPS (under working temperature) |

| Max working pressure | 20MPa |

| Max fluid temperature | 80°C |

| Max output | 10kg/min |

| Max heated hose length (Optional) | 60m |

| Heater power | 4500Wx2 |

| Heated hose max power | 2000W |

| Drive mode | Full pneumatic |

| Clean mode | Self-cleaning by air |

| Voltage (Optional) | Single phase 220V 50Hz or Three phase 380V 50Hz |

| Whole power | 11kw |

| Pneumatic source | 0.5-0.8Mpa 1m³/min |

Product Uses

Here are some specific application scenarios of pu foam spray machinery:

1. Two component polyurethane foam spray machine can be used in construction building roof and wall insulation.

2. Two component pu foam machine can be used in pipe insulation with injection gun, it can also spray&injection on tank for insulation.

3. Two component foaming spray machine can be used in cold storage thermal insulation, and mobile home insulation, and container, car interior thermal insulation.

4. Two component rigid foam spraying machine can be also used in Industrial commercial purpose , such as chicken house insulation project, door panel injection foam projects, cold storage house panel insulation, Greenhouse insulation projects, and so on...

Standard Configuration:

1 set mainframe, 1 set spray gun, 2 sets transfer pump, 15m heated hose,2 pcs transfer pump hose, 2 pcs whip hose, 1 set air pipe, 1 set tools and spare parts, 1 set English user manual,1 set protective clothing and mask .

Product Introduction

Reanin K2000 portable polyurethane spray machine is a pneumatic two-component polyurethane spray injection machine. It is suitable for building interior and exterior wall and roof insulation, pipe insulation, economical, easy to operate and maintain, and is an indispensable sprayer in the polyurethane technical solution.

Product Advantage

1."Reanin-K2000 Portable Pu Foam Spray Insulation Machine": Customers can achieve a variety of spraying tasks with the versatility of the Reanin-K2000 portable polyurethane spray machine.

2."Competitive Factory Price": The Reanin-K2000 spray foam insulation machine is offered at a highly competitive factory price, making it an attractive and cost-effective solution for users.

3."Full Pneumatic Drive Model": The Reanin-K2000 features a full pneumatic drive model, ensuring superior performance and effectiveness in a variety of spraying tasks, including foam insulation jobs.

4."Self-Cleaning by Air": The machine offers a user-friendly self-cleaning system, where cleaning can be done easily and quickly, saving users time and effort.

5."Core Components of Motor": The product's key selling points also include the use of superior core components such as a motor, pump, and engine, which ensure the machine's reliability and durability over the 1-year warranty period.

Technical Parameters

| Model | Reanin-K2000 Polyurethane Spray Machine |

| Applicable materials | Polyurethane |

| The ratio of raw material | 1:1 |

| Viscosity range of raw materials | 200-1000CPS (under working temperature) |

| Max working pressure | 20MPa |

| Max fluid temperature | 80°C |

| Max output | 10kg/min |

| Max heated hose length (Optional) | 60m |

| Heater power | 4500Wx2 |

| Heated hose max power | 2000W |

| Drive mode | Full pneumatic |

| Clean mode | Self-cleaning by air |

| Voltage (Optional) | Single phase 220V 50Hz or Three phase 380V 50Hz |

| Whole power | 11kw |

| Pneumatic source | 0.5-0.8Mpa 1m³/min |

Product Uses

Here are some specific application scenarios of pu foam spray machinery:

1. Two component polyurethane foam spray machine can be used in construction building roof and wall insulation.

2. Two component pu foam machine can be used in pipe insulation with injection gun, it can also spray&injection on tank for insulation.

3. Two component foaming spray machine can be used in cold storage thermal insulation, and mobile home insulation, and container, car interior thermal insulation.

4. Two component rigid foam spraying machine can be also used in Industrial commercial purpose , such as chicken house insulation project, door panel injection foam projects, cold storage house panel insulation, Greenhouse insulation projects, and so on...

Standard Configuration:

1 set mainframe, 1 set spray gun, 2 sets transfer pump, 15m heated hose,2 pcs transfer pump hose, 2 pcs whip hose, 1 set air pipe, 1 set tools and spare parts, 1 set English user manual,1 set protective clothing and mask .