loading

K2000

Reanin

8424899990

| polyurethane foam for wall insulation | pu foam spraying for wall insulation | pu foaming for car interior insulation |

|  |  |

| pu foaming for car interior insulation | K2000 polyurethane foam spray insulation machine | polyurethane foam injection in pipe for insulation |

|  |  |

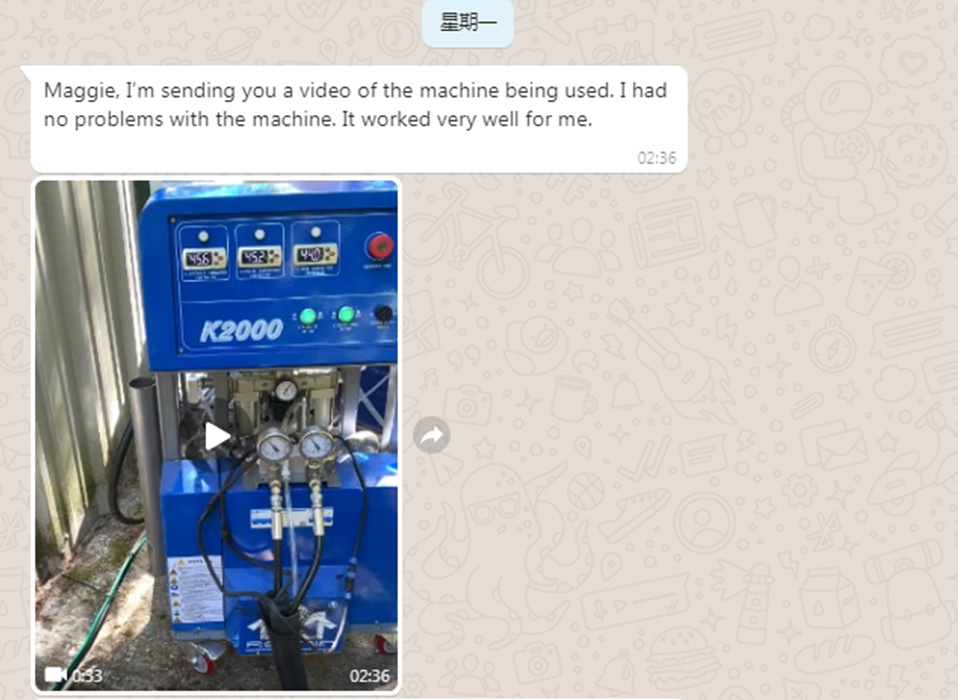

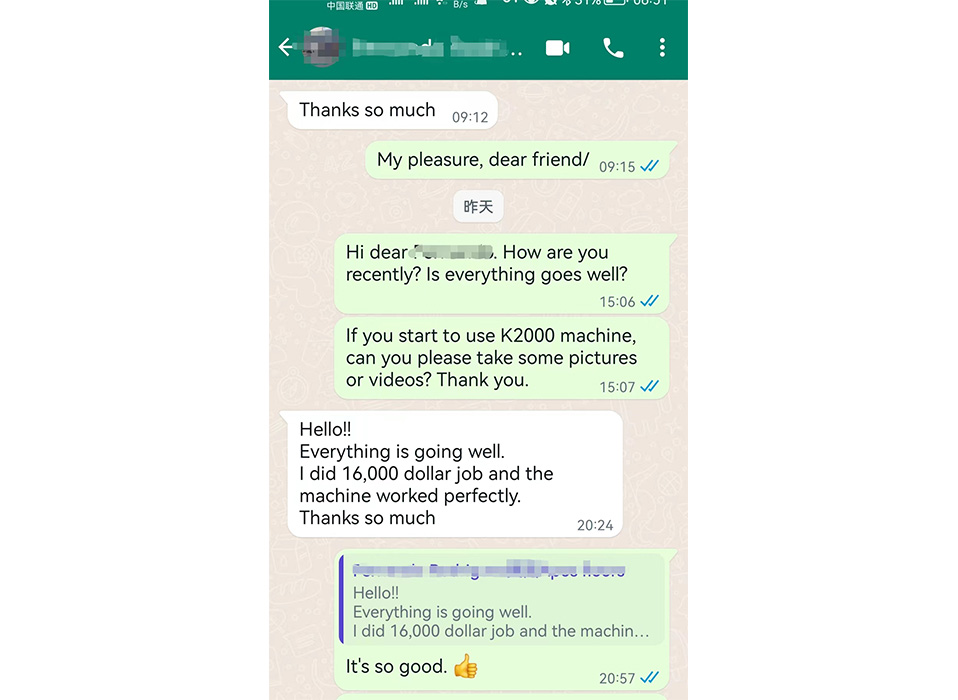

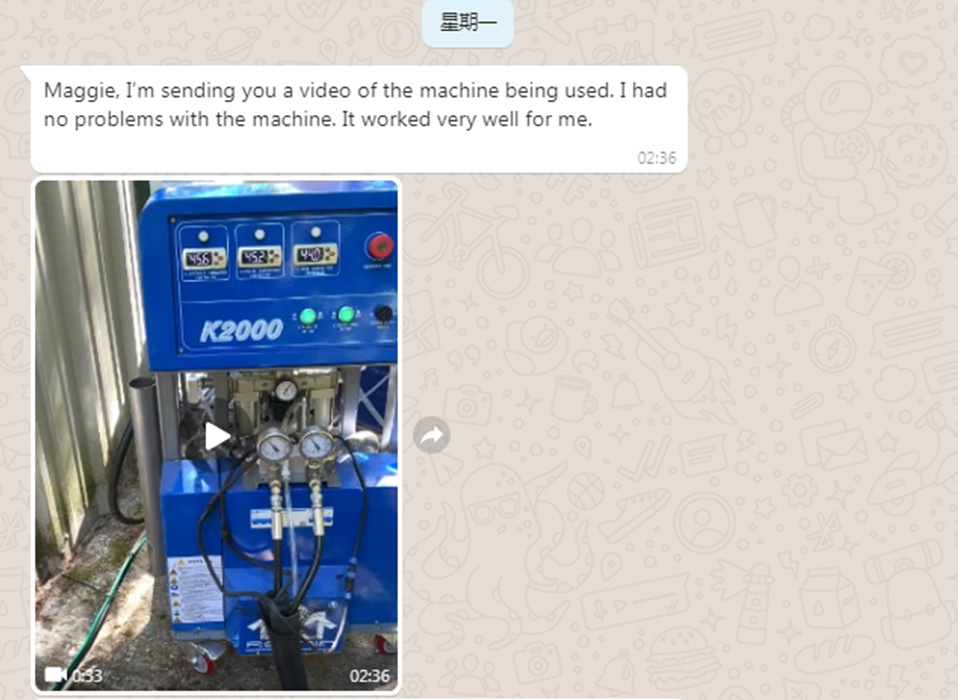

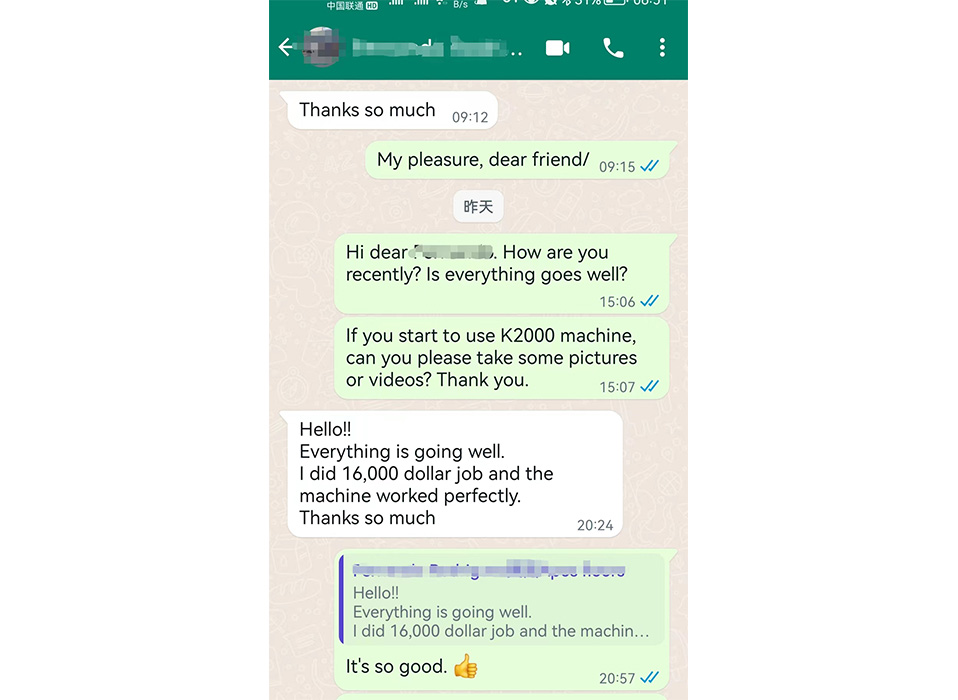

Product Introduction

Reanin K2000 portable polyurethane spray machine is a pneumatic two-component polyurethane spray injection machine. It is suitable for building interior and exterior wall and roof insulation, pipe insulation, economical, easy to operate and maintain, and is an indispensable sprayer in the polyurethane technical solution.

Product Advantage

•This machine has pass the CE Certificate,

•Panel with operation tips is easy to set up,

•Fully pneumatic design, it can work normally without electricity,

•The booster pump is simple in structure and easy to disassemble and maintain,

•The stop reset function can make the booster pump shafts always infiltrated in the booster pump, which can avoid damage to the seals and booster pump shafts caused by ISO crystallization,

•A/B/Hose independent temperature control, can set different temperatures separately, adapt to the temperature requirements of different material,

•Variable frequency temperature control mode and special real-time temperature collection sensor ensure that the material temperature is controlled within a small fluctuation range,

•The integrated heated hose is covered with wear-resistant insulating sleeve, which not only can effectively keep the temperature of the material, but also can prevent the occurrence of leakage, short circuit, etc.

•The transfer pumps, mainframe and spray gun are equipped with filtering devices, which can effectively filter impurities and crystals in the materials and reduce the occurrence of the blocking gun,

•High-precision pressure gauges are available in MPa and PSI to meet the needs of different customers,

•Equipped with an action counter to accurately calculate the amount of raw materials,

•The spray gun is made of alloy material, light weight, less wearing parts, easy to use and maintain.

Technical Parameters

| Model | Reanin-K2000 Polyurethane Spray Machine |

| Applicable materials | Polyurethane |

| The ratio of raw material | 1:1 |

| Viscosity range of raw materials | 200-1000CPS (under working temperature) |

| Max working pressure | 20MPa |

| Max fluid temperature | 80°C |

| Max output | 10kg/min |

| Max heated hose length (Optional) | 60m |

| Heater power | 4500Wx2 |

| Heated hose max power | 2000W |

| Drive mode | Full pneumatic |

| Clean mode | Self-cleaning by air |

| Voltage (Optional) | Single phase 220V 50Hz or Three phase 380V 50Hz |

| Whole power | 11kw |

| Pneumatic source | 0.5-0.8Mpa 1m³/min |

Product Uses

Here are some specific application scenarios of pu foam spray machinery:

1. Two component polyurethane foam spray machine can be used in construction building roof and wall insulation.

2. Two component pu foam machine can be used in pipe insulation with injection gun, it can also spray&injection on tank for insulation.

3. Two component foaming spray machine can be used in cold storage thermal insulation, and mobile home insulation, and container, car interior thermal insulation.

4. Two component rigid foam spraying machine can be also used in Industrial commercial purpose , such as chicken house insulation project, door panel injection foam projects, cold storage house panel insulation, Greenhouse insulation projects, and so on...

Standard Configuration:

1 set mainframe, 1 set spray gun, 2 sets transfer pump, 15m heated hose,2 pcs transfer pump hose, 2 pcs whip hose, 1 set air pipe, 1 set tools and spare parts, 1 set English user manual,1 set protective clothing and mask .

| polyurethane foam for wall insulation | pu foam spraying for wall insulation | pu foaming for car interior insulation |

|  |  |

| pu foaming for car interior insulation | K2000 polyurethane foam spray insulation machine | polyurethane foam injection in pipe for insulation |

|  |  |

Product Introduction

Reanin K2000 portable polyurethane spray machine is a pneumatic two-component polyurethane spray injection machine. It is suitable for building interior and exterior wall and roof insulation, pipe insulation, economical, easy to operate and maintain, and is an indispensable sprayer in the polyurethane technical solution.

Product Advantage

•This machine has pass the CE Certificate,

•Panel with operation tips is easy to set up,

•Fully pneumatic design, it can work normally without electricity,

•The booster pump is simple in structure and easy to disassemble and maintain,

•The stop reset function can make the booster pump shafts always infiltrated in the booster pump, which can avoid damage to the seals and booster pump shafts caused by ISO crystallization,

•A/B/Hose independent temperature control, can set different temperatures separately, adapt to the temperature requirements of different material,

•Variable frequency temperature control mode and special real-time temperature collection sensor ensure that the material temperature is controlled within a small fluctuation range,

•The integrated heated hose is covered with wear-resistant insulating sleeve, which not only can effectively keep the temperature of the material, but also can prevent the occurrence of leakage, short circuit, etc.

•The transfer pumps, mainframe and spray gun are equipped with filtering devices, which can effectively filter impurities and crystals in the materials and reduce the occurrence of the blocking gun,

•High-precision pressure gauges are available in MPa and PSI to meet the needs of different customers,

•Equipped with an action counter to accurately calculate the amount of raw materials,

•The spray gun is made of alloy material, light weight, less wearing parts, easy to use and maintain.

Technical Parameters

| Model | Reanin-K2000 Polyurethane Spray Machine |

| Applicable materials | Polyurethane |

| The ratio of raw material | 1:1 |

| Viscosity range of raw materials | 200-1000CPS (under working temperature) |

| Max working pressure | 20MPa |

| Max fluid temperature | 80°C |

| Max output | 10kg/min |

| Max heated hose length (Optional) | 60m |

| Heater power | 4500Wx2 |

| Heated hose max power | 2000W |

| Drive mode | Full pneumatic |

| Clean mode | Self-cleaning by air |

| Voltage (Optional) | Single phase 220V 50Hz or Three phase 380V 50Hz |

| Whole power | 11kw |

| Pneumatic source | 0.5-0.8Mpa 1m³/min |

Product Uses

Here are some specific application scenarios of pu foam spray machinery:

1. Two component polyurethane foam spray machine can be used in construction building roof and wall insulation.

2. Two component pu foam machine can be used in pipe insulation with injection gun, it can also spray&injection on tank for insulation.

3. Two component foaming spray machine can be used in cold storage thermal insulation, and mobile home insulation, and container, car interior thermal insulation.

4. Two component rigid foam spraying machine can be also used in Industrial commercial purpose , such as chicken house insulation project, door panel injection foam projects, cold storage house panel insulation, Greenhouse insulation projects, and so on...

Standard Configuration:

1 set mainframe, 1 set spray gun, 2 sets transfer pump, 15m heated hose,2 pcs transfer pump hose, 2 pcs whip hose, 1 set air pipe, 1 set tools and spare parts, 1 set English user manual,1 set protective clothing and mask .