Product Overview

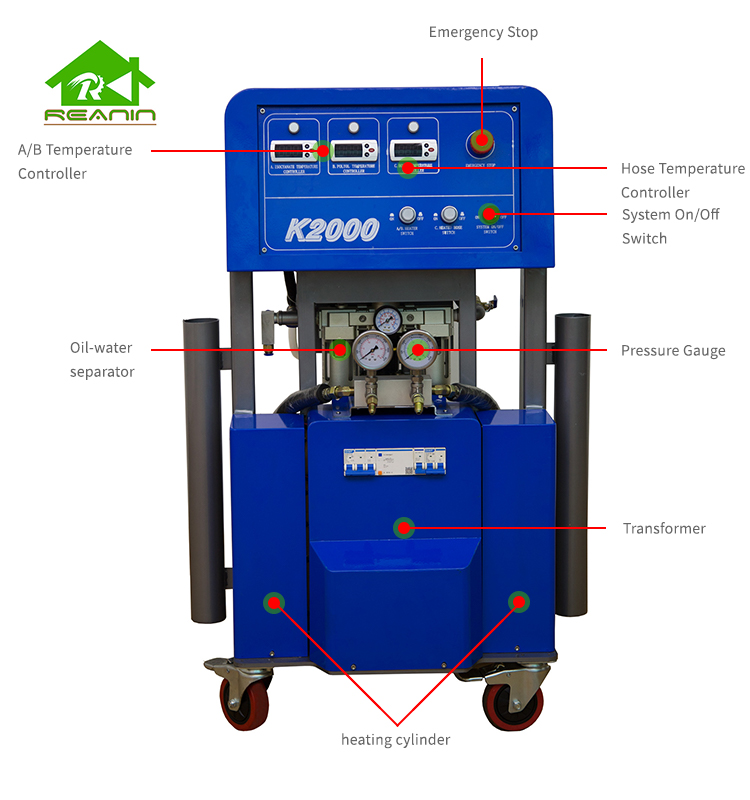

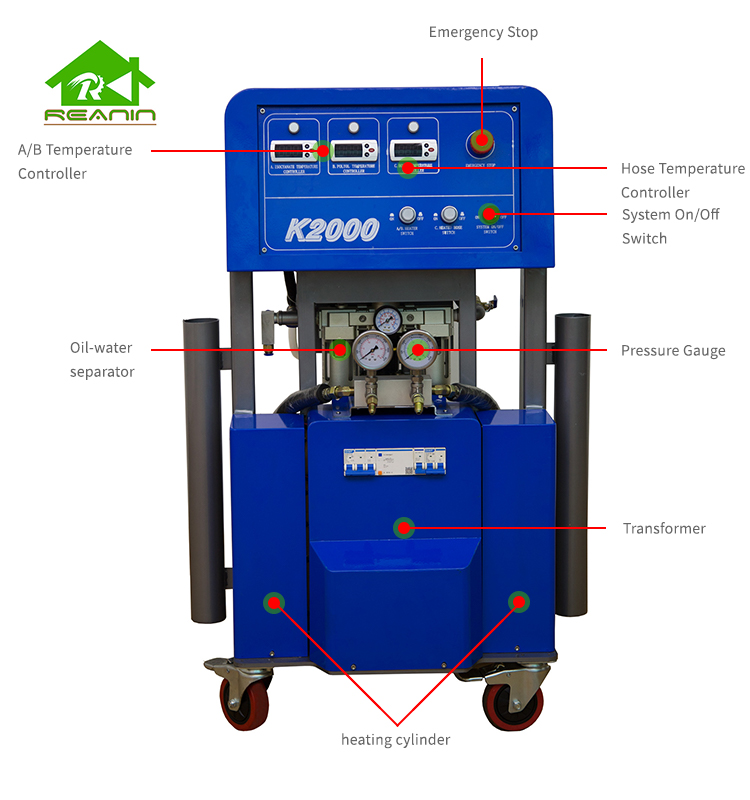

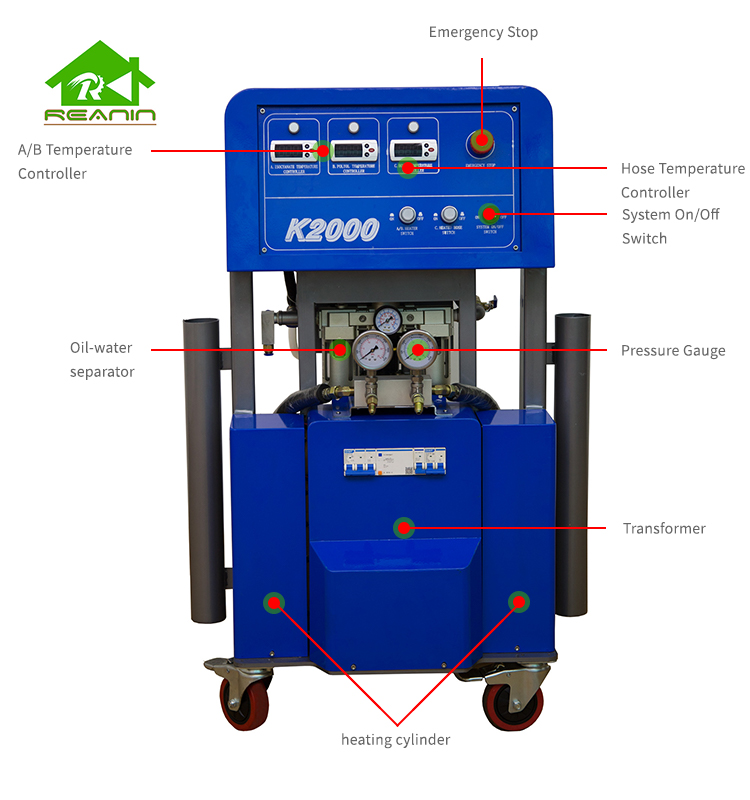

Transform your insulation projects with the Reanin K2000, a professional-grade portable polyurethane foam spraying system designed for contractors who demand reliability, precision, and efficiency. This compact yet powerful machine delivers commercial-quality insulation results while maintaining the portability and ease-of-use that modern construction professionals require.

Product Description

Imagine completing your insulation projects 40% faster while using 30% less material - that's the reality contractors experience with the Reanin K2000. Unlike bulky traditional systems that require multiple operators and extensive setup time, this innovative sprayer puts professional-grade insulation capability in the hands of a single technician.

The Reanin K2000 isn't just another spray foam machine; it's your competitive advantage in today's demanding insulation market. When winter temperatures drop and your competitors are struggling with equipment failures, you'll be applying perfect foam beads at optimal temperature, thanks to our advanced dual-zone heating system. The whisper-quiet pneumatic operation means you can work in residential areas without disturbing homeowners, while the ergonomic spray gun reduces operator fatigue during extended projects.

Every component of the K2000 has been engineered with real-world job site challenges in mind. The self-cleaning pneumatic system eliminates costly downtime from clogged lines, while the precision pressure control ensures consistent foam density from the first spray to the last. Whether you're insulating a 2,000 square foot attic or sealing critical joints in a commercial building, the K2000 delivers the reliability and performance that separates professional contractors from weekend warriors.

Product Advantage

•This machine has pass the CE Certificate,

•Panel with operation tips is easy to set up,

•Fully pneumatic design, it can work normally without electricity,

•The booster pump is simple in structure and easy to disassemble and maintain,

•The stop reset function can make the booster pump shafts always infiltrated in the booster pump, which can avoid damage to the seals and booster pump shafts caused by ISO crystallization,

•A/B/Hose independent temperature control, can set different temperatures separately, adapt to the temperature requirements of different material,

•Variable frequency temperature control mode and special real-time temperature collection sensor ensure that the material temperature is controlled within a small fluctuation range,

•The integrated heated hose is covered with wear-resistant insulating sleeve, which not only can effectively keep the temperature of the material, but also can prevent the occurrence of leakage, short circuit, etc.

•The transfer pumps, mainframe and spray gun are equipped with filtering devices, which can effectively filter impurities and crystals in the materials and reduce the occurrence of the blocking gun,

•High-precision pressure gauges are available in MPa and PSI to meet the needs of different customers,

•Equipped with an action counter to accurately calculate the amount of raw materials,

•The spray gun is made of alloy material, light weight, less wearing parts, easy to use and maintain.

Key Features & Highlights

Professional Performance in a Portable Package

-

Maximum output of 10kg/min covers large areas efficiently

-

20MPa working pressure ensures deep penetration and superior adhesion

-

60-meter heated hose capability reaches every corner of your project

-

CE certification guarantees compliance with international safety standards

Advanced Temperature Control System

-

Independent A/B component temperature control prevents material waste

-

Real-time temperature monitoring with ±2°C accuracy

-

Rapid heating system reaches optimal temperature in under 15 minutes

-

Insulated hose system maintains temperature over extended distances

Built for Reliability

-

Fully pneumatic operation eliminates electrical hazards

-

Self-cleaning system reduces maintenance time by 70%

-

High-precision filtering prevents gun clogging

-

Aircraft-grade aluminum spray gun for durability and reduced weight

Operator-Centric Design

-

Intuitive control panel with clear operation prompts

-

Ergonomic spray gun reduces wrist strain by 40%

-

Integrated action counter for accurate material tracking

-

Quick-connect fittings for rapid setup and breakdown

Technical Parameters

| Model | Reanin-K2000 Polyurethane Spray Machine |

| Applicable materials | Polyurethane |

| The ratio of raw material | 1:1 |

| Viscosity range of raw materials | 200-1000CPS (under working temperature) |

| Max working pressure | 20MPa |

| Max fluid temperature | 80°C |

| Max output | 10kg/min |

| Max heated hose length (Optional) | 60m |

| Heater power | 4500Wx2 |

| Heated hose max power | 2000W |

| Drive mode | Full pneumatic |

| Clean mode | Self-cleaning by air |

| Voltage (Optional) | Single phase 220V 50Hz or Three phase 380V 50Hz |

| Whole power | 11kw |

| Pneumatic source | 0.5-0.8Mpa 1m³/min |

Application Scenarios

Residential Insulation ExcellenceTransform drafty homes into energy-efficient sanctuaries. The K2000 excels in attic insulation, creating seamless thermal barriers that reduce energy costs by up to 50%. Wall cavity injection capabilities ensure complete coverage without thermal bridging, while the precise control system prevents over-expansion that can damage drywall.

Commercial Building SolutionsFrom warehouse ceilings to office partition walls, deliver consistent R-value performance across large commercial spaces. The 60-meter hose capability means fewer equipment relocations, while the high-output system maintains productivity on extensive projects. Create air-tight building envelopes that meet the most stringent energy codes.

Specialized Industrial ApplicationsMobile home underbellies, shipping container conversions, and cold storage facilities all benefit from the K2000's versatility. The system's ability to handle varying ambient temperatures makes it ideal for climate-controlled environments, while the portable design navigates tight industrial spaces with ease.

Standard Configuration:

1 set mainframe, 1 set spray gun, 2 sets transfer pump, 15m heated hose,2 pcs transfer pump hose, 2 pcs whip hose, 1 set air pipe, 1 set tools and spare parts, 1 set English user manual,1 set protective clothing and mask .

Why Choose Reanin K2000?

Proven Track RecordWith over 1,000 satisfied customers across 30 countries, Reanin has established itself as a trusted name in polyurethane equipment manufacturing. Our 2,000 square meter production facility incorporates ISO 9001 quality management systems, ensuring every K2000 meets rigorous performance standards.

Total Cost of OwnershipWhile competitors focus on initial purchase price, we engineer for lifetime value. The K2000's efficient material usage saves an average of $2,000 annually in foam costs compared to entry-level systems. Maintenance requirements are 60% lower than hydraulic alternatives, with most servicing completed in under 30 minutes using standard tools.

Comprehensive Support NetworkTechnical issues don't follow business hours, which is why our support team provides 24/7 assistance in English, Spanish, and Portuguese. Each K2000 includes detailed video training resources, while our regional service centers ensure parts availability within 48 hours anywhere in North America or Europe.

Future-Ready TechnologyInvestment in the K2000 means staying ahead of evolving building codes and environmental regulations. Our R&D team continuously updates firmware and hardware components, with upgrade paths that extend equipment life rather than requiring complete replacement.

Shandong Reanin Machinery Co., Ltd.

Shandong Reanin Machinery Co., Ltd is one of the leading manufacturers of polyurethane and polyurea equipment in China. It has a modern production plant of over 2,000 square meters and an excellent team of engineers. Our products has been exported to more than 30 countries and regions, serves more than one thousand customers around the world. Welcome to contact us!

Frequently Asked Questions

Q: How does the pneumatic system compare to electric or hydraulic alternatives?A: Pneumatic operation offers superior reliability in challenging environments. Without electric motors or hydraulic fluids, the K2000 operates safely in wet conditions and extreme temperatures. The system provides instant response without motor lag, while eliminating the fire hazards associated with hydraulic systems. Maintenance is simplified to filter changes and basic lubrication.

Q: What's the learning curve for technicians new to spray foam?A: Most operators achieve proficiency within 2-3 projects. The K2000's intuitive controls and consistent material delivery eliminate the guesswork common with basic systems. We provide comprehensive training materials including video tutorials, troubleshooting guides, and best practice documentation. Technical support is available throughout your first six months of operation.

Q: How do you ensure consistent foam quality in varying weather conditions?A: The dual-zone temperature control system automatically compensates for ambient conditions. Independent heating of A and B components ensures proper chemical reaction regardless of external temperature. The insulated hose system maintains material temperature from heater to gun, while real-time monitoring alerts operators to any deviations from optimal parameters.

Q: What maintenance schedule should we follow?A: Daily maintenance requires 15 minutes: flush the system, check filters, and lubricate key components. Weekly maintenance adds pump inspection and pressure testing. Monthly service includes comprehensive filter replacement and calibration verification. The self-cleaning system eliminates the extensive flushing required by competitor units, while modular design allows component replacement without specialized tools.

Q: Can the K2000 handle different foam formulations?A: The system accommodates all major polyurethane formulations with viscosity ranges from 200-1000 CPS. Temperature and pressure settings adjust automatically based on material specifications. Whether you're applying closed-cell insulation foam, open-cell sound dampening foam, or specialized roofing formulations, the K2000 delivers consistent results.

Q: What warranty and service options are available?A: Every K2000 includes a comprehensive 2-year warranty covering all components except wear items. Extended warranty options provide coverage up to 5 years. Our service network includes certified technicians in 40+ locations, with remote diagnostic capabilities for rapid issue resolution. Training programs ensure your team maximizes equipment performance while maintaining warranty compliance.